CNC Milling

Milling

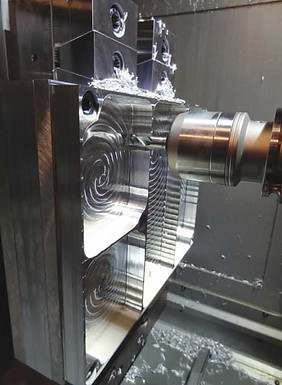

CNC milling is the selective removal of material from a block using a cutter that follows a path defined by a program. The machine tool has multiple axes to accomplish the task. Typically, mills have 3 axes: X,Y,&Z that correspond to length, width, and height. We have a 3 axis, 4 axis (extra axis allows for rotating the part), and 5 axis (we can now rotate the part in 2 planes) mills.

CNC milling is the most utilized process in our work. We have 3 CNC milling machines. 2 Vertical Machining Centers (VMC's) - Machines that have a spindle mounted vertically and 1 Horizontal Machining center (HMC) in which the spindle is mounted horizontally. HMC's are typically larger, more rigid, allow for better chip removal, and have multiple pallets to allow for faster setup times.

At FP&M we can put our mills to work for you, whether it is a prototype or single replacement part, or thousands. We look forward to hearing about your project!